How Fuel is Carried from the Injector Pump to Inlet

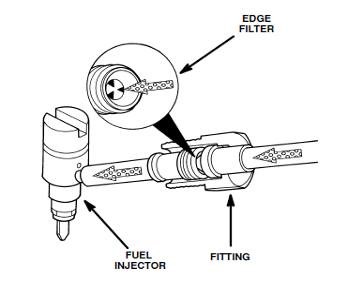

Fuel under high pressure needs to be transported from the pump or rail to the injector inlet in order to run the engine and give your truck power it needs. This is done through the injector inlet connector tube, also called fuel feed tube. It is positioned through the side of the cylinder head.

The seal between this tube and the injector is straight metal to metal. No other materials can be used because the torque rate needs to be so specific to ensure a proper seal. If the appropriate level torque is not used, the diesel engine could experience high-pressure fuel leaks. These would stem directly from tube or inlet surface deformation or simply a gap where the seal should be tight. Injector misses and low engine power can occur.

Between the fuel tube fitting and fuel injector, a connector tube’s edge filter provides protection for the engine from contaminants in the fuel. The filter reduces the size of any foreign particles down to 10 microns or less. This size should not be damaging to the fuel injector assembly.

It is important to note that this edge filter cannot be accessed for cleaning or changing. If it gets plugged or damaged in any way, the entire connector tube will need to be replaced.

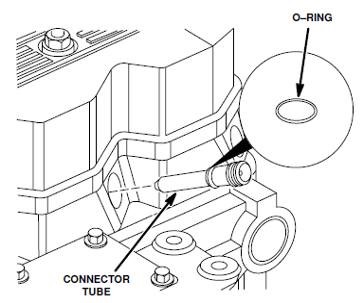

Any time you have access to the connector to, whether it is being installed for the first time or replaced, check the condition of the connector tube O-ring and replace it if necessary. To ensure a proper seal all the time, replacing it whenever the opportunity arises is a good idea.

At the same time, inspect the fuel tube completely. If any damage, wear, or improper torque is witnessed, consider a new connector tube installation. The last thing you want to do is disassemble the fuel system again if the engine is misfiring or the driver complains of low power.

Diesel Done Right.